The Straub coupling is an innovation in the field of pumping technology. That has been revolutionizing the way people move water, wastewater, and other liquids. One of the most exciting features of this kind of coupling is its ability to reduce friction, resulting in better efficiency and easier use at the same time. In this article, we’ll go over the basics of how this works and explain how you can get your hands on one if you’re interested in testing it out yourself.

What Is The Straub Coupling?

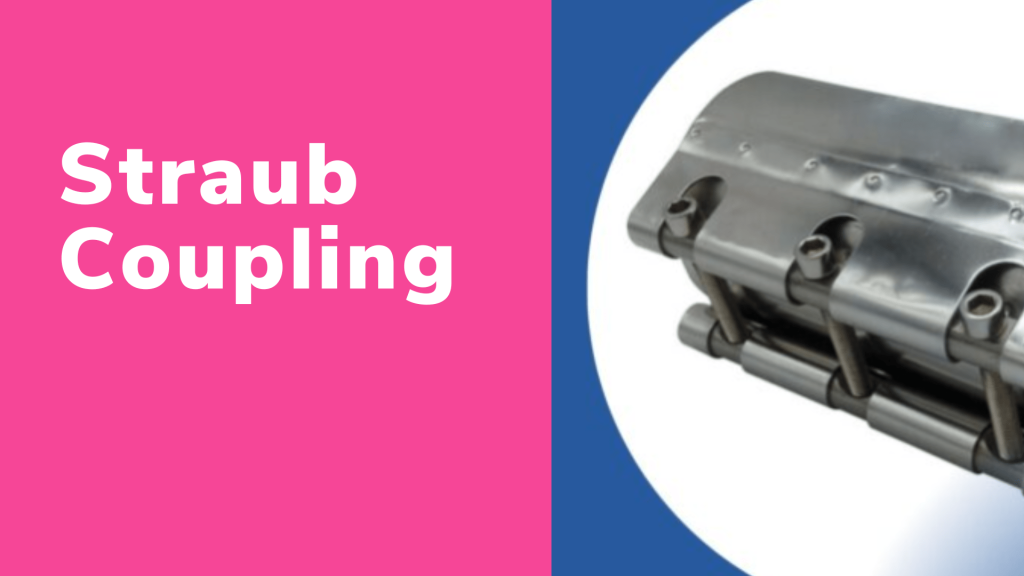

An external coupling device such as the Straub coupling can be used in fluid power. It is commonly used on continuous-duty pumps, since it allows a high pressure to be delivered through a thinner tube. Fluid flowing through one tube squeezes fluid out of another tube in much the same way as air is squeezed out of a balloon when it is blown up. With The Straub coupling, two pumping systems are connected by tubing and internal tubing to ensure that there is no backflow during use.

What Are The Advantages Of Using The Straub Coupling?

The great thing about Straub couplings is that they have few disadvantages. One of their biggest advantages is that they are highly versatile and work well with both liquids and gases. These coupling can handle high pressures and high temperatures. There are very few types of liquid or gas that a Straub coupling cannot withstand, making them an excellent option for almost any job. One problem with these couplings is that there is not much room for error when working with them. So it’s important to get professional help if you plan on using them in your home or workplace.

How to use straub couplings in a pumping system

Use straub couplings to connect components in a pumping system. Note that straub couplings are not suitable for use with peristaltic pumps. Because they cause a degree of turbulence in fluid flow. In many ways, straub couplings are similar to yoke unions: both consist of two parts (male and female) which can be joined together by twisting them.

Tips for proper use of straub couplings

When operating a straub coupling, it’s important to remember that there is always resistance in a seal. Over time, seals can wear out or get loose and need to be replaced. In some cases, seals can get so loose that they completely fail and leak while pumping. A major way of reducing seal wear is to use a proper scraper tool. When opening and closing couplings on pipe. Keeping your scraper sharp helps prevent damage to the sealing surface of straub couplings. Additionally, if you use a hub-seal straub coupling instead of an O-ring straub coupling. You are less likely to have problems with water intrusion through broken O-rings. Which can damage both your pump seals and potentially also crack your pump casing itself.

The bottom line

Often, when farmers are looking to improve their pumping efficiency, they reach for a different pump. But before you pull out your wallet and invest in an upgrade. Consider applying some straub coupling technology to your existing pumps. A straub coupling can help balance these hydraulics better than a standard pump barrel. To learn more about how straubs can reduce wear on your equipment—and keep your fields pumping at maximum efficiency—click here .