What is an Industrial Pump and What are Its Types?

Ever wondered which type of pump to go for or which pumps would be beneficial to your industry? Well, if so, then read on. In this article, we will look at what an industrial pump is and what are its types. So, without further ado, let’s get straight to it.

What is an industrial pump?

An industrial pump is used to displace various kinds of products like chemicals, water, petroleum, wastewater, oil, food, etc. We will even go through ARO (air-operated diaphragm pump), PP pump and chemical process pumps.

Now that we know what an industrial pump is, let us take a look at its types.

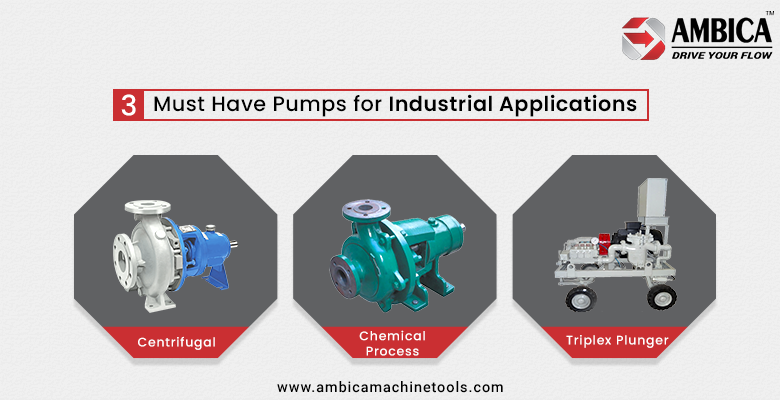

Centrifugal pumps

Centrifugal pump, also known as dynamic pressure pump or hydrodynamic pump is the most commonly used in diverse industries.. centrifugal pump is used to transport liquids – can be water or other fluids from one location to another. The fluid is transported through the conversion of rotational kinetic energy to the hydrodynamic energy of the liquid’s flow and this rotational energy comes from an engine or an electric motor.

These types of pumps are used for any fluid with low viscosity in industrial, domestic or agricultural applications. If you are looking for a centrifugal pump manufacturer, consider your industry and applications of the pump. If you want a pump to transport low viscosity fluids, then centrifugal pumps will be the best option for you.

Air-operated diaphragm pumps

ARO pumps are majorly used for general fluid transfer. Unlike centrifugal pumps, these pumps can even easily transport fluids from light to medium viscosity. In fact, they can pump solid particles too without any damage. The primary benefit of these type of pumps is that it has versatility in materials, performance, and design and can handle almost all types of fluids.

They are used to transfer, empty, fill, and meter bases, acids or fluids (even fluids containing solid particles). An air operated diaphragm pump manufacturer can help you understand whether you should go for this pump or any other depending on your application.

Chemical process pumps

These types of pumps are widely known for their low life cycle cost and are also less durable under extreme conditions. They are generally used in the chemical process, petrochemical industries or petroleum industries. There are many types of chemical process pumps that can reduce the overall process cost by improving the operation and efficiency of process systems. Due to this, a chemical process pump has more advantages over centrifugal pumps.

Chemical process pumps are appropriate for the transfer of corrosive chemicals, plating chemicals, acids, dyes, solvents, hazardous & fuming liquids, petrol, kerosene, and other similar substances.

PP pump

A PP pump (Polypropylene Pump) is used for chemicals including salt water, DI water, acidic water, Citric Acid, Fluosilicic Acid, Formaldehyde, and many more salts. These types of pumps are used in dyes, chemicals and petrochemical plants, fertilizer, food and dairy industries, etc.

Wrapping up

By now, you might have understood industrial pumps and their types. However, you need to understand your requirements and make a purchase accordingly.