What is Warehouse Management System?

Customer service can make or break a corporation. Customers want speedier fulfilment and are less tolerant of mistakes or late deliveries. When consumers have a problem, they don’t hesitate to post it on review sites, social media, or even your website. Customers read reviews and consider them when making purchasing decisions, according to 81% of customers.

If you make too many mistakes, your reputation will suffer. It’s also possible that you’ll get kicked off Amazon or other eCommerce marketplaces with strict reputation management policies.

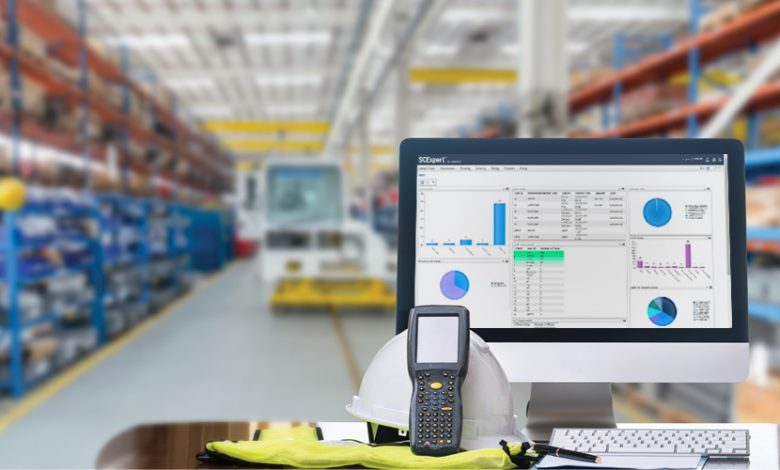

Warehouse Management System

(WMS) is a type of software that handles inventory management, picking processes, reporting, and auditing in a warehouse. Your warehouse management system (WMS) is an important component of your warehouse supply chain.

When you place an order with your vendors, the supply chain begins. Each item’s path through your ecosystem is tracked by your warehouse management system and your inventory management system (IMS) as it is received, stored, picked, packed, and sent.

Items are entered into your system when they arrive. As products are stored, your warehouse management system will keep track of them. When it’s time to ship, it can construct paperless and optimal routes for pickers to retrieve things using real-time inventory data.

A Warehouse Management System’s Basic Components

Receiving and returns, warehouse logistics, third-party software connectors, and powerful forecasting and reporting tools are all important components of a warehouse management system.

Returns and Receiving

A warehouse management system (WMS) keeps track of stock receipts and returns. By reducing the amount of superfluous products in storage, a good WMS may help businesses save money. Similarly, by keeping correct real-time amounts, a WMS can help prevent out-of-stocks and oversells.

Maintaining adequate inventory balance is one of the fundamental goals of warehouse management software.

Logistics in the Warehouse

Your warehouse inventory system will also take care of modelling and controlling the logical representation of actual storage facilities and racking.

This is usually an area where a WMS may make a considerable difference in terms of efficiency. It’s simple to understand how any efficiency can result in considerable cost savings.

Most warehouse operational budgets include 65 percent labour costs. It lowers your operational costs if you can make your warehouse personnel more efficient. The time spent travelling to retrieve items can account for up to half of the time spent picking.

Integrations

In order to select, pack, and transport items out of the facility quickly, you’ll need to provide a smooth connectivity between order processing and logistics management.

To track sales across several online marketplaces, you’ll need warehouse inventory software that interfaces with channel management software. It should also work with a number of industry-standard technologies, such as online marketplaces, shipping solutions, and online store platforms, to help you run your business.

Forecasting and reporting

Another key element of warehouse management software is the ability to track product whereabouts, supply routes, and storage. This allows you to better manage your inventory and warehouse space.

Data-driven reporting and forecasting tools help you make smarter business decisions. The inventory management system generates reports that illustrate which SKUs are selling best or fastest, the best pricing and stock levels, historical data, and more.

Also read: Why is SEO Important for your Web Site